Warehouse And Logistics

Jmorxe introduces a new solution for the logistics industry, covering various aspects of warehousing and logistics, assisting in RFID identification, detection, measurement, and precise positioning, promoting refined control over the logistics process. Our photoelectric sensors, distance measuring sensors, inductive sensors, light curtains, encoders, and other devices are used in vertical automated warehouses, stacker cranes, and various stages of conveying, sorting, and storage operations in the logistics industry.

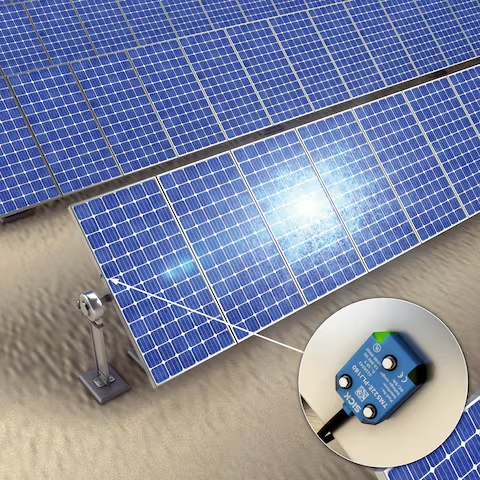

Energy Equipment

The photoelecric sensor/proximity sensor produced by Jmorxe are widely used in photovoltaic production equipment, such as photovoltaic silicon wafer manufacturing, inspection/ testing equipment. They are also utilized in lithium battery production equipment, including winding machines, stacking machines, coating machines, and string welding machines, providing precised detection solutions for new energy production equipment. Jmorxe’s high-precision displacement sensors can detect defects in photovoltaic wafer and inspect batteries for defective products. The high-precision CCD linear diameter sensor can be used to correct the deviation of the rolled material in the winding machine. The laser displacement sensor is used for thickness detection of adhesive in coating machines.

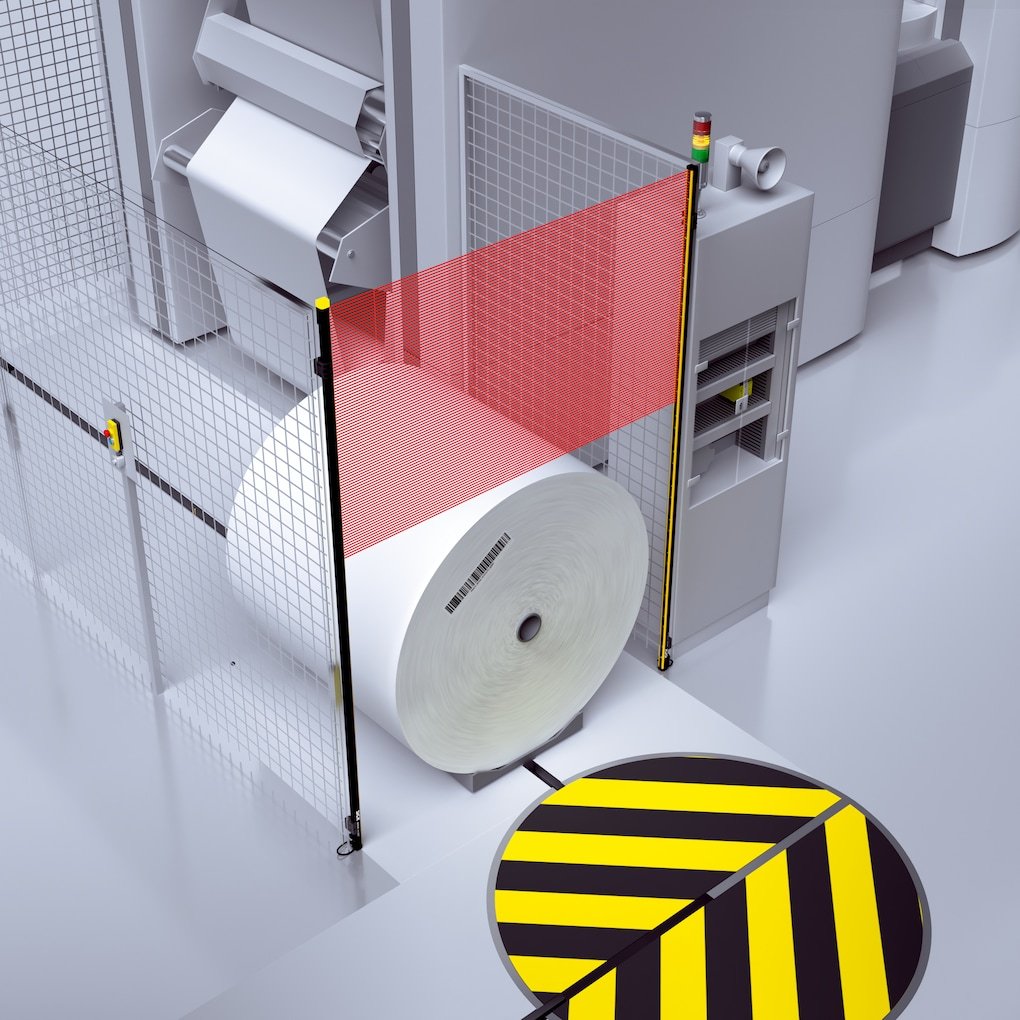

Security

Jmorxe’s light curtain sensor, such as JM-S series Installed on both sides of the safety door of the coating machine for safety protection. Also can be used in many other fields. Customized and ajustable safety sensors are available here.

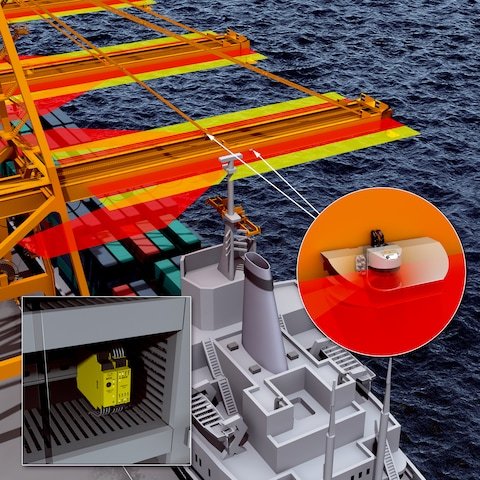

Outdoor Automation

Jmorxe sensors are widely used in daily life, especially in outdoor automation. For example, they are used to check the condition of road microstructures, railway superstructures, bridge construction, collision-free container handling, anti-collision measures for aircraft passenger boarding bridges, measuring ship inclination, distinguishing containers of different lengths, hydraulic testing, object detection on industrial cranes, monitoring the terminal position of telescopic systems, anti-collision measures for dock crane booms, volume measurement of bulk materials, rear collision warnings for excavators through LIDAR sensors, position recognition of harvesters, and distribution of conveyor belt positions.