How does the sensor used on the packaging machine?

Packaging machines often use various types of sensors to ensure proper operation and quality control. Some common types of sensors used on packaging machines include:

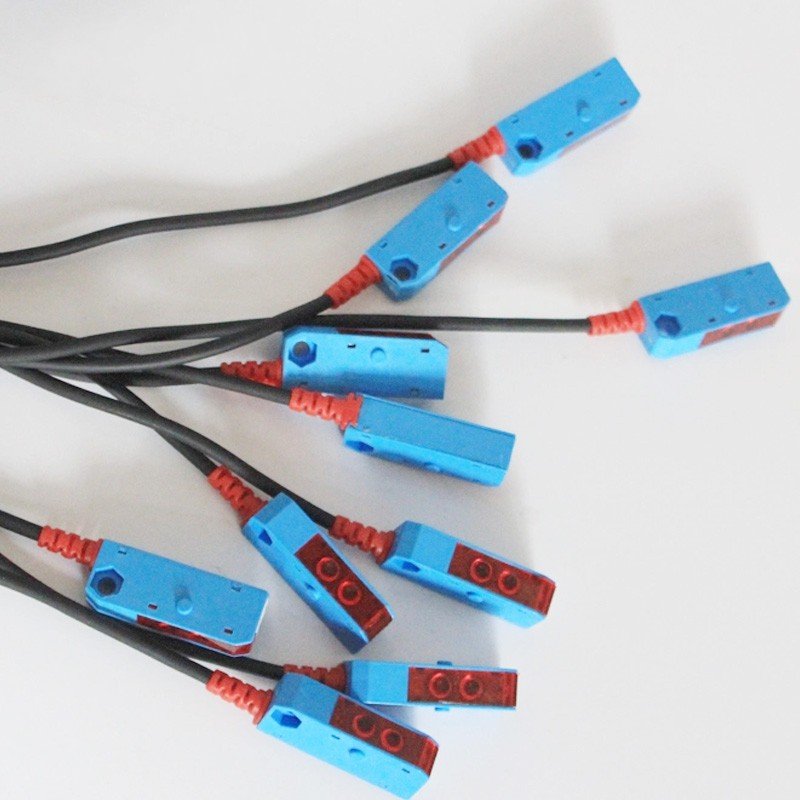

Proximity sensors: Proximity sensors are used to detect the presence of an object near the sensor without any physical contact. These sensors can be used to detect the presence of packaging materials or products at various stages of the packaging process.

Photoelectric sensors: Photoelectric sensors use a beam of light to detect the presence or absence of an object. These sensors are often used to detect the position of products on a conveyor belt or to ensure proper labeling or printing on packaging materials.

- Pressure sensors: Pressure sensors are used to monitor and control the pressure levels in pneumatic or hydraulic systems within the packaging machine. These sensors help ensure that the machine operates within safe pressure limits and can also be used to detect jams or blockages in the packaging process.

4.Vision sensors: Vision sensors use cameras and image processing algorithms to inspect products for defects, verify label placement, or ensure proper packaging. These sensors are often used for quality control purposes to guarantee that products meet specific standards before being packaged.

5.Temperature sensors: Temperature sensors are used to monitor the temperature of various components within the packaging machine, such as heating elements or cooling systems. These sensors help ensure that the machine operates within the required temperature range for proper packaging.

Overall, sensors play a crucial role in ensuring the efficiency, accuracy, and quality of packaging processes in modern packaging machines. By providing real-time data and feedback, sensors help optimize production, minimize errors, and ensure consistent product quality.